Side Bend Ribbon Lighting Silicone Neon Strip Lights

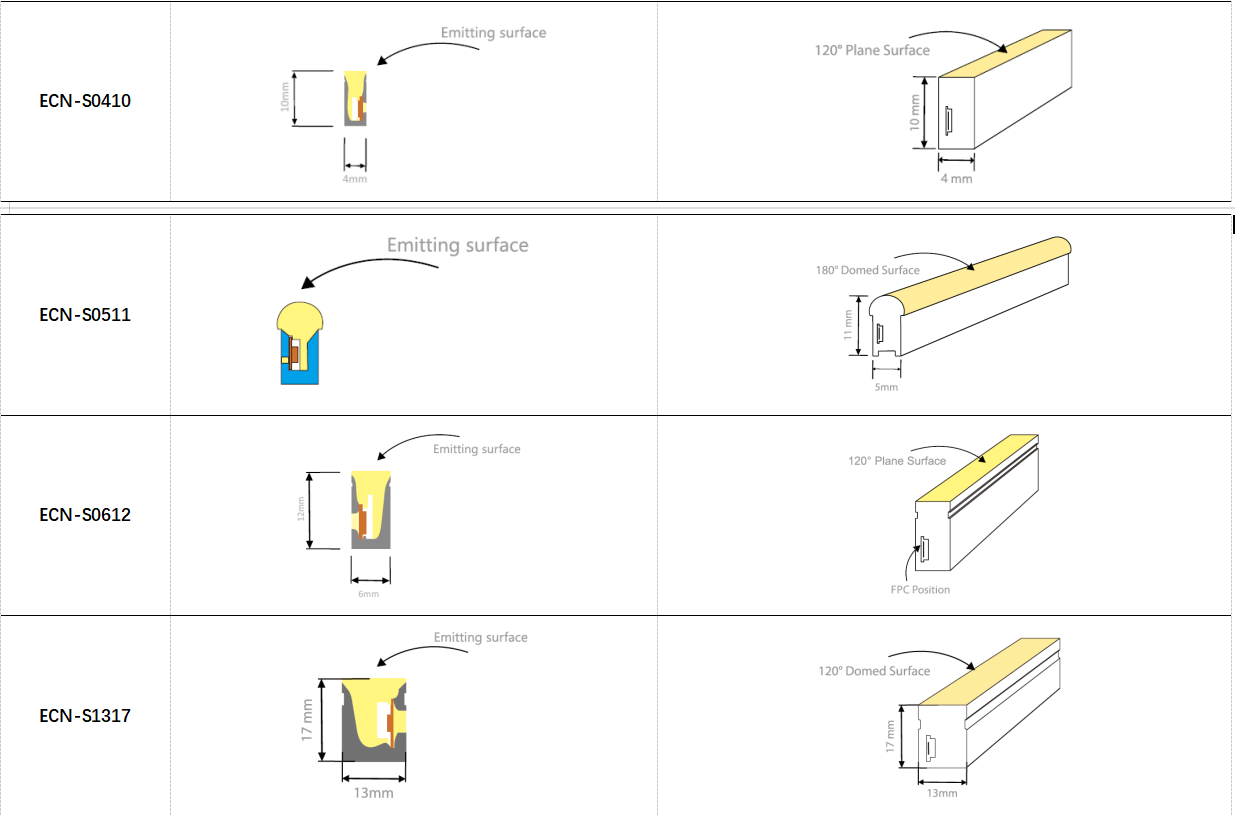

ECN-S0410

ECN-S0511

ECN-S0612

S1317

Structure Specification

Brief Introduction

Top Bend Series

Top bend series neon LED strip, bending direction: vertical. This series adopt environmental silicone material, up to IP67 protection level. High light transmission, can be used for sign lighting, indoor and outdoor decorative lighting and architecture contour lighting molding.

Side Bend Series

Side bend series neon LED strip, bending direction: horizontal. This series adopt unique optical structure design and no shadow. Side bending design can be used for building outline, indoor and outdoor decorative lighting and other scenes. IP68 high protection level, suit for swimming pool underwater lighting.

Flexible neon LED strip lights adopt flexible silicone material, strong plasticity, combined with top bend, side bend two type lighting surfaces, meeting the lighting needs of indoor decoration, landscape lighting, architectural curtain walls, building outline and other scenes. Neon strip lighting series adopt innovative technology, no dark area. Can be applied in straight line, circular, curved, and other special shape. It is the best partner for your space design and artistic molding.

Adheres to independent R&D and sustaining innovation, and our products passed the ISO9001 QMS & ISO14001 EMS certification. All products have passed the testing of the third-party authoritative laboratories and have attained the quality certification from a variety of countries and regions: CE, REACH, ROHS, UL, TUV, LM-80 and so on.

Basic Parameters

|

Model |

CCT/Color |

CRI |

Input Voltage |

Rated Current |

Rated Power |

Lumens or Wavelength (LM) |

Size (mm) |

Cutting Unit (mm) |

Max. Length |

IP Process |

|

ECN-S0410 |

2300K |

>90 |

24V |

0.38 |

9W/m |

205 |

W4*H10 |

55 |

5000mm |

IP67 |

|

2700K |

225 |

|||||||||

|

3000K |

250 |

|||||||||

|

4000K |

280 |

|||||||||

|

6000K |

280 |

|||||||||

|

R |

/ |

620-630nm |

||||||||

|

G |

520-530nm |

|||||||||

|

B |

465-475nm |

|||||||||

|

Model |

CCT/Color |

CRI |

Input Voltage |

Rated Current |

Rated Power |

Lumens or Wavelength (LM) |

Size (mm) |

Cutting Unit (mm) |

Max. Length |

IP Process |

|

ECN-S0511 |

2300K |

>90 |

24V |

0.38 |

9W/m |

290 |

W5*H11 |

55 |

5000mm |

IP67 |

|

2700K |

325 |

|||||||||

|

3000K |

360 |

|||||||||

|

4000K |

400 |

|||||||||

|

6000K |

400 |

|||||||||

|

R |

/ |

620-630nm |

||||||||

|

G |

520-530nm |

|||||||||

|

B |

465-475nm |

|||||||||

|

Model |

CCT/Color |

CRI |

Input Voltage |

Rated Current |

Rated Power |

Lumens or Wavelength (LM) |

Size (mm) |

Cutting Unit (mm) |

Max. Length |

IP Process |

|

ECN-S0612 |

2300K |

>90 |

24V |

0.38 |

9W/m |

295 |

W6*H12 |

55 |

5000mm |

IP67 |

|

2700K |

330 |

|||||||||

|

3000K |

365 |

|||||||||

|

4000K |

405 |

|||||||||

|

6000K |

405 |

|||||||||

|

R |

/ |

620-630nm |

||||||||

|

G |

520-530nm |

|||||||||

|

B |

465-475nm |

|||||||||

|

Model |

CCT/Color |

CRI |

Input Voltage |

Rated Current |

Rated Power |

Lumens or Wavelength (LM) |

Size (mm) |

Cutting Unit (mm) |

Max. Length |

IP Process |

|

ECN-S1317 |

2300K |

>90 |

24V |

0.46 |

11W/m |

450 |

W13*H17 |

55 |

5000mm |

IP67 |

|

2700K |

500 |

|||||||||

|

3000K |

550 |

|||||||||

|

4000K |

600 |

|||||||||

|

6000K |

600 |

|||||||||

|

R |

/ |

620-630nm |

||||||||

|

G |

520-530nm |

|||||||||

|

B |

465-475nm |

Note:

1. The above data is based on the testing result of 1meter standard product.

2. The power and lumens of output data can be varied up to ±10%.

3. The above parameters are all typical values.

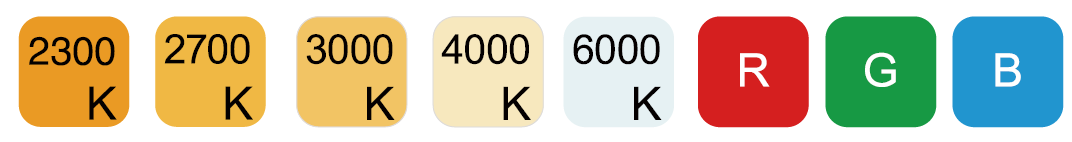

CCT/Color Options

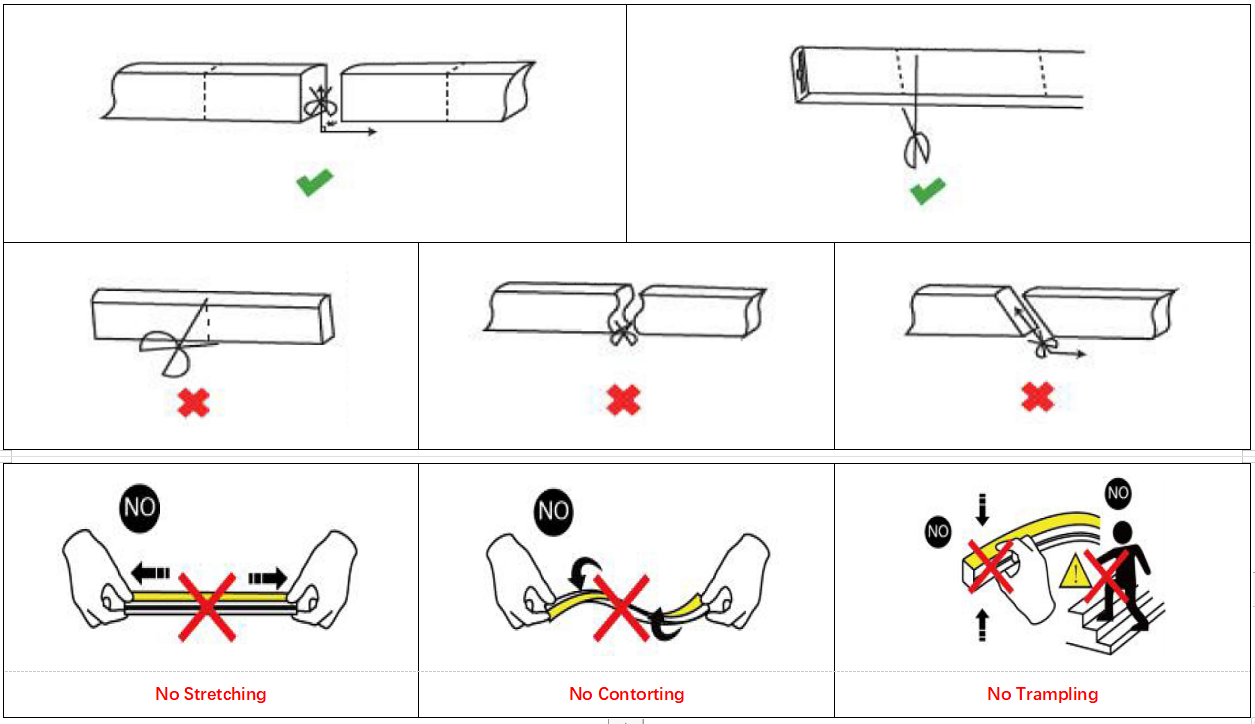

Cutting Method

Installation Instructions

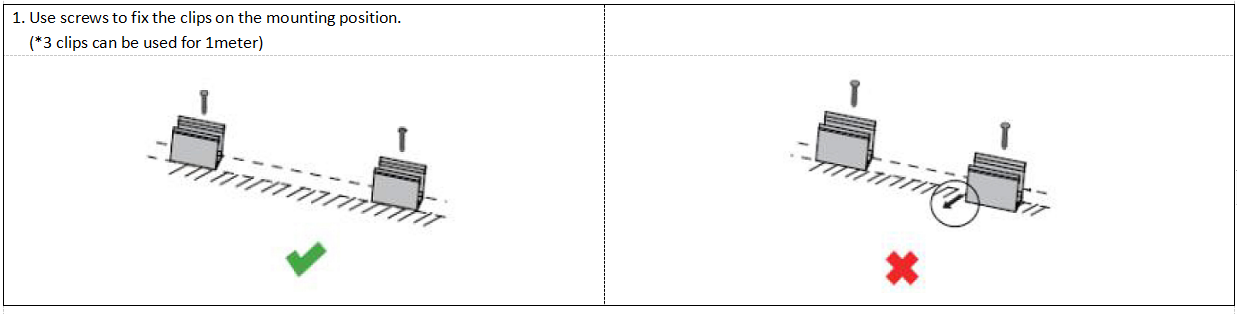

Installation of clips

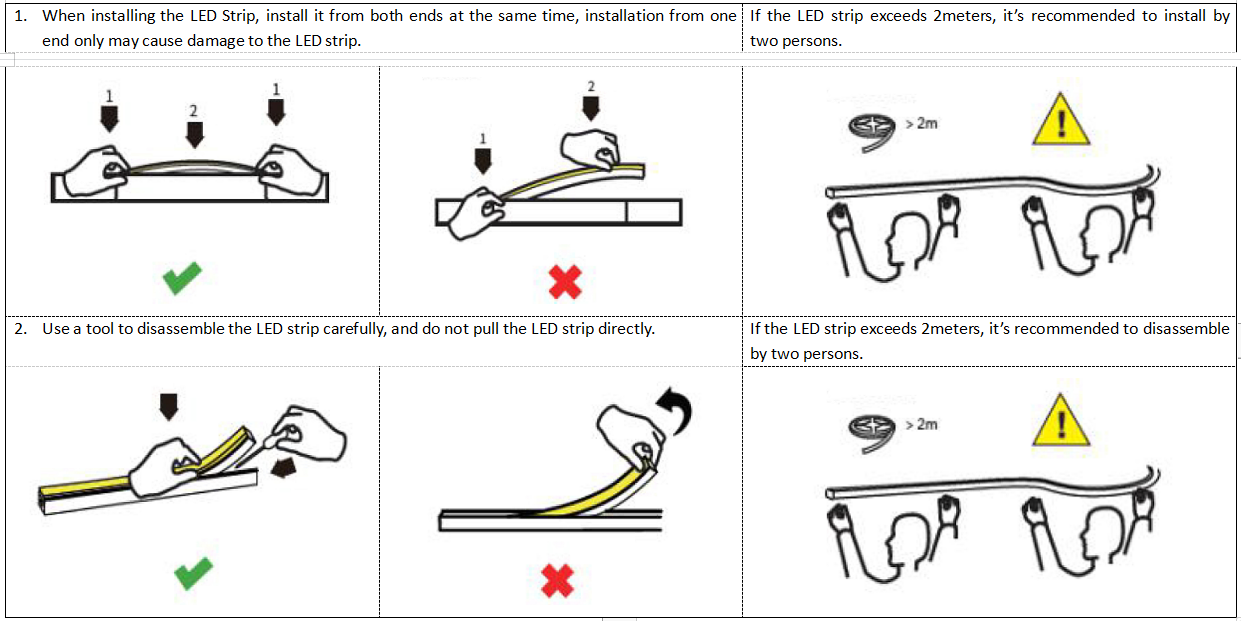

Installation of carriers

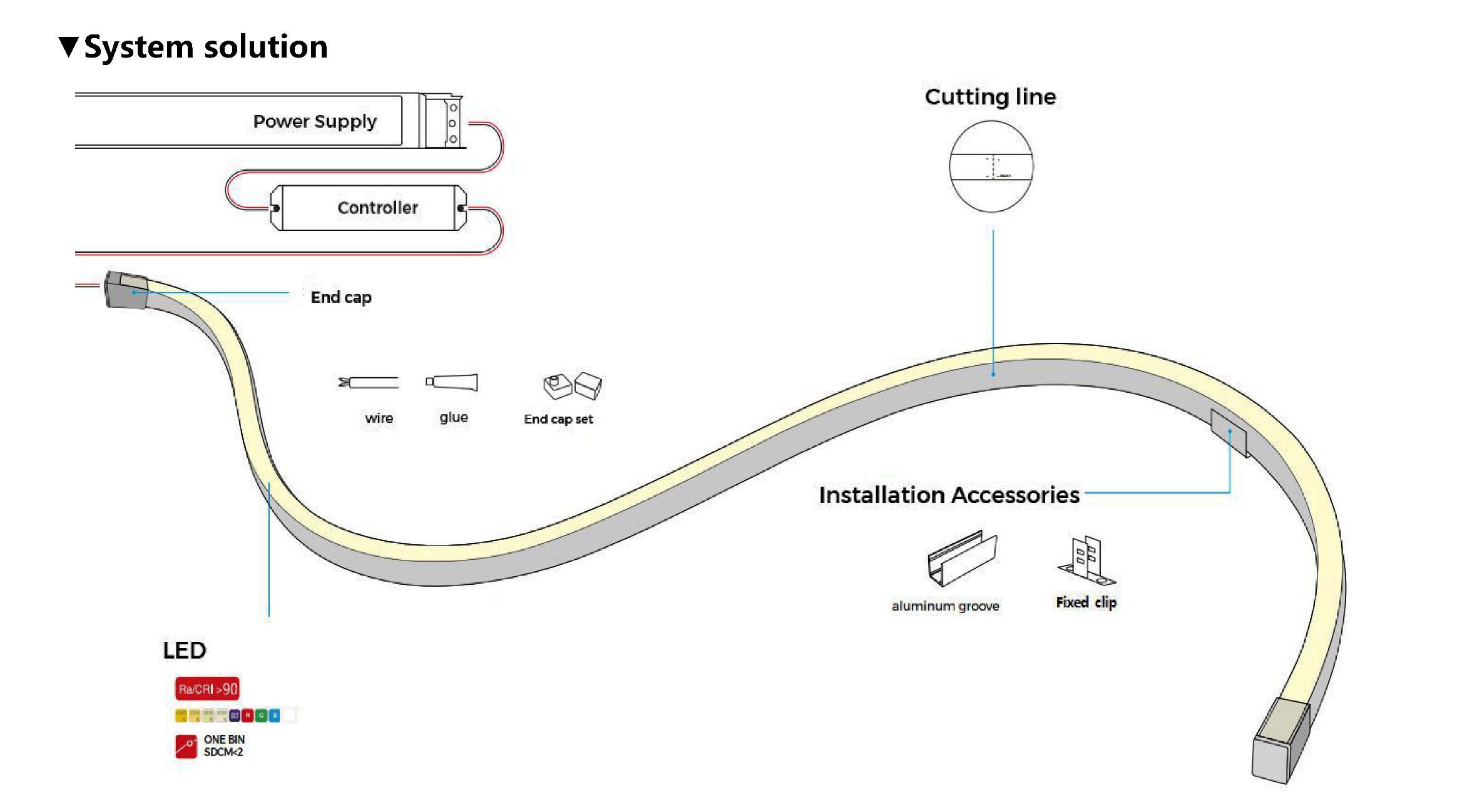

System Solutions

Packing Details

|

5m/reel |

Electrostatic Bag 1reel/bag |

20 bags/carton 100m/carton |

Precautions

※ Please drive the led strip with required isolated power, and the ripple of the constant voltage source should be less than 5%.

※ Please do not bend the strip into an arc with a diameter less than 60mm to ensure the longevity and reliability.

※ Do not fold it in case any damage of LED beads.

※ Do not pull the power wire hard to ensure the longevity. Any Crash may damage the LED light is prohibited.

※ Please make sure the wire is connected to the anode and cathode correctly. The power output should be consistent with the voltage of the strip to avoid damage.

※ LED lights should be stored in dry, sealed environment. Please only unpack it before usage. Ambient temperature: -25℃~40℃.

Storage temperature: 0℃~60℃.Please use the strips without waterproof within indoor environment with humidity less than 70%.

※ Please be careful during operation. Do not touch the AC power supply in case of electric shock.

※ Please leave at least 20% power for the power supply during using to ensure there is enough power supply to drive the product.

※ Do not use any acid or alkaline adhesives to fix the product (e.g.: glass cement).

Related PRODUCTS

-

Phone

-

E-mail

-

Top